Preston And Olin Building

Early History

Originally constructed 1855 as a three-story, 100 x 40-ft. brick edifice; located on a hill to northeast of present Henderson Hall and faced the length of Main Street. Constructed, possibly by John N. Lyle, to house Olin and Preston Institute, a school for boys opened by local Methodists in 1851 and chartered by the state on Feb. 28, 1854. During the Civil War, Maj. Gen. George C. Crook used the building as his headquarters while his federal troops passed through Blacksburg following the Battle of Cloyd’s Mountain. At the time, the building was empty because the institute had closed during the Civil War. In 1869 the Methodists opened another school at the site: the Preston and Olin Institute, which received a charter from the state on Jan. 2, 1869. When the institute successfully pursued Virginia’s land-grant monies, the deed to the building was signed over to the trustees of the Virginia Agricultural and Mechanical College (Virginia Tech’s first name). At the time, the building contained three recitation rooms, a chapel, and 24 lodging rooms.

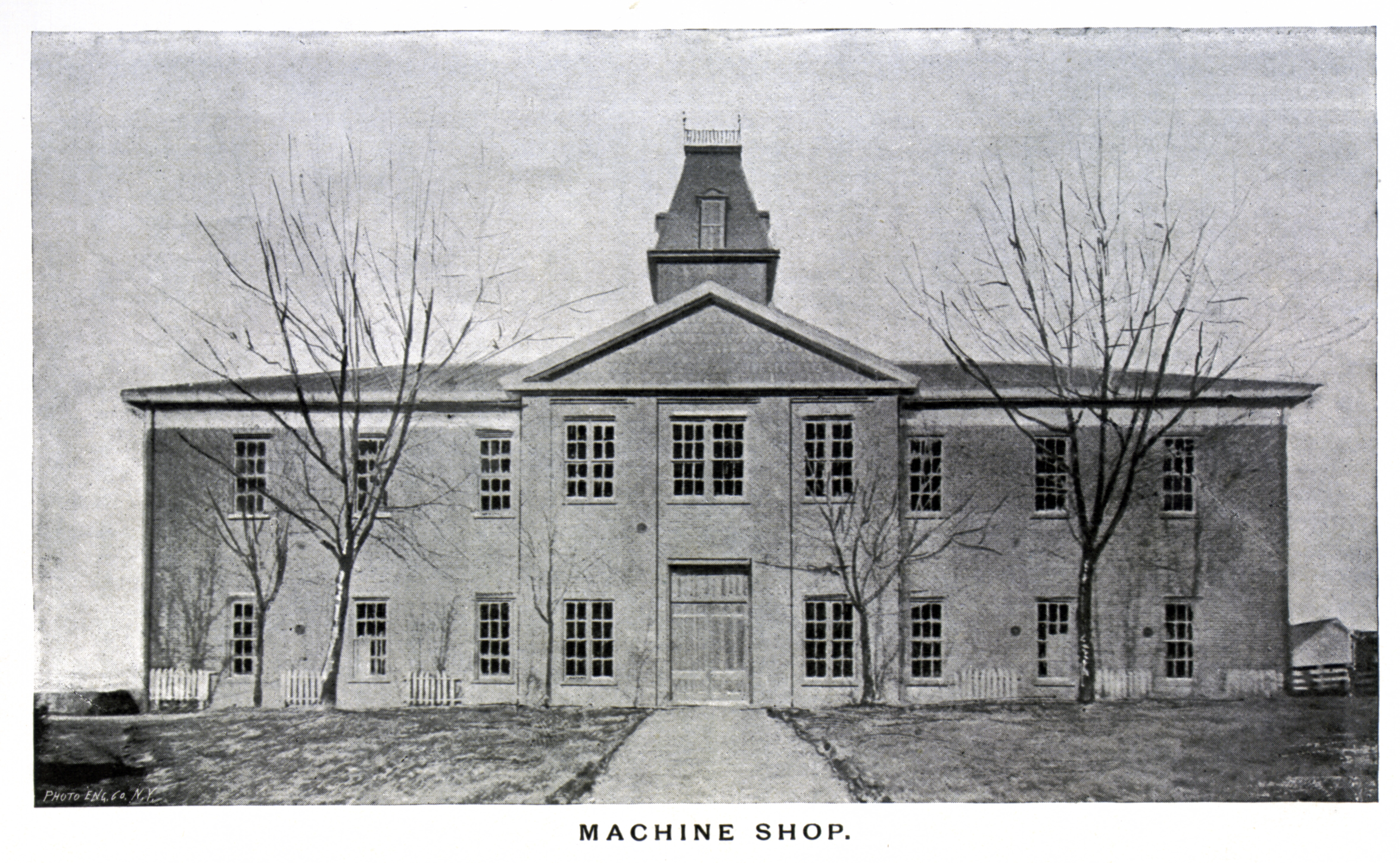

In 1888, after students moved into Barracks No. 1, the building was remodeled by General Lomax and converted into the Machine Shop.

The following description is taken from the Catalogue of the Virginia Agricultural and Mechanical College, 1891-’92, pp. 46-48

The Shop Building

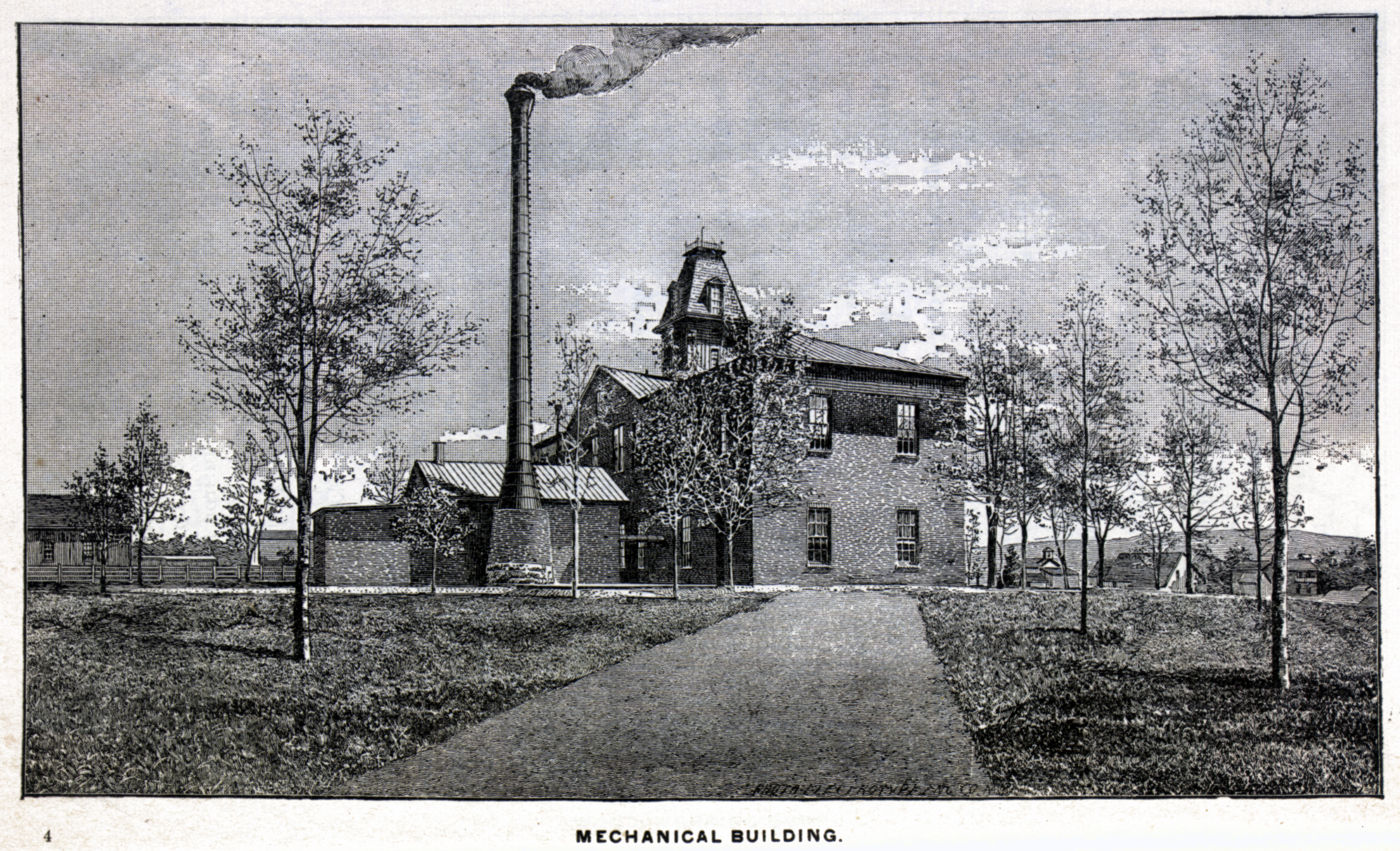

Equipment. — The shops occupy a two-story brick building, with boiler and coal-house detached. The main building is 40 by 110 feet. The machine shop, the supply room and the engine room are on the first floor; the wood-working room is on the second floor, and the store rooms for lumber in the attic. The wash room is between the two floors. Power is furnished by a fifty-horse power Buckeye engine, which also drives the electric light dynamo. This is connected to the main head shaft by a friction clutch, so that the shafting of the shops can be started or stopped at pleasure without interfering with the engine. The shafting of each room is also connected with its head shaft by a clutch. Steam is generated by a battery of two sixty-power horizontal return tubular boilers, fitted with all modern appliances. One supplies sufficient steam for our needs and the other is kept in reserve. The shops throughout are heated by exhaust steam from the engine and lighted by incandescent electric lights.

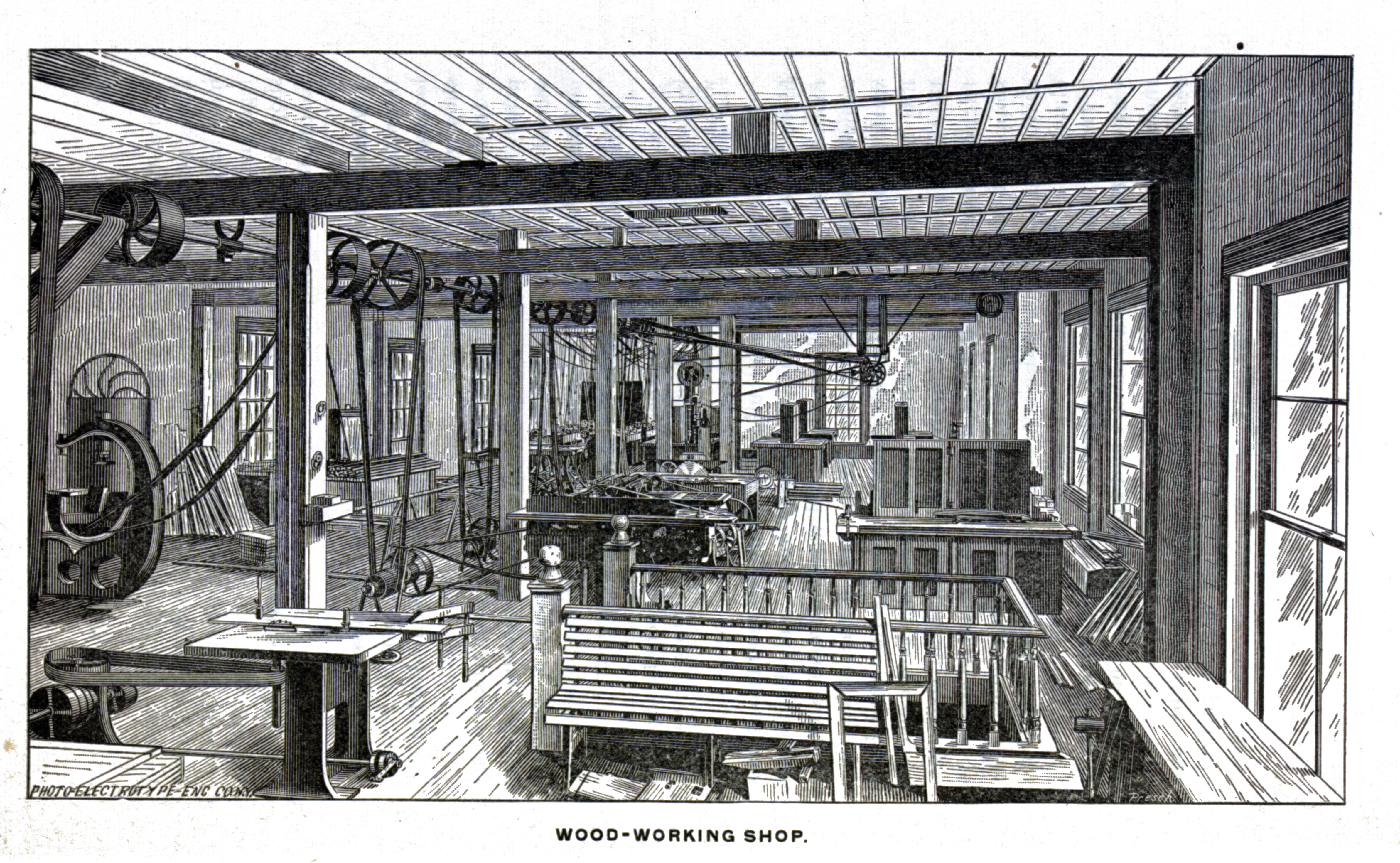

The Wood-working room is 40 X 110 feet, and contains eighteen work-benches (described below); twelve 12"x5’ turning lathes (described below); one large turning lathe, one combination rip and cut-off circular-saw, one large circular-saw, one hand-saw, one scroll-saw, one mortising and boring machine, a reversible shaper, one double-headed universal wood-worker, one 24" surface planer with tonguing and grooving attachment, one Daniel’s planer, one steam glue-heater and one steaming-box. The work-benches are 8x2-1/2 feet, strongly and neatly built of oak. Below are two closets, and at the back of the top are two tool-cases, each case containing the following tools: One rip-saw, one panel-saw, one tennon-saw, one joint-plane, one jack-plane, one smoothing-plane, one block-plane, one claw-hammer, one mallet, one set of chisels, one set of gouges, one screw-driver, one scriber, one framing-square, one try-square, one bevel-square, one marking and mortise-gauge, one pair of compasses, one bit-brace, one set bits, one brad-awl, one oil-stone, one oil-can, one rule and one dust-brush. Each bench is fitted with a Massey’s vise; one bench accommodates two students working on alternate days, each student having exclusive use of one set of tools and one closet. The turning lathes are equipped similarly to the benches, each lathe having two sets of tools. Each set is arranged on a system of boards, and kept when not in use in cases under the lathe; when used these boards are placed on the rear end of the lathe, where the tools can be easily reached by the student at work. A set of lathe tools includes three turning gouges, three turning chisels, one parting tool, one pair of calipers, one pair of dividers, one hammer, one oil-stone, one slip-stone, one oil-can, and one dust-brush. As with the benches, each lathe accommodates two students on alternate days, each student having a set of tools and a case to himself. Sixteen feet is cut off at one end of this room; a part of this space is used as the instructor’s office. Among other things kept in this office is a complete set of tools not in such frequent demand as to necessitate their being included in the regular sets. The remaining part of the space is made dust proof, and used as a finishing-room.

The Machine Shop occupies a space 80x40 feet, and contains eleven work-benches (described below), one 14"x6′ Flather engine lathe with taper attachment, two 14"x6" Flather engine lathes, three 17"x5′ Muller engine lathes, one 16"x8′ Reed engine lathe, one 10"x5′ Reed engine lathe, one 12"x4" Diamond hand lathe, one 10" speed lathe, one 15" Walcott shaper, one 10"x10"x22" Hendy planer, one 24"x24"x5′ Gray planer, one No. 15 Brainard universal milling machine, one 18" Reed drill press, one emery grinding machine, one grinding stone, one pipe vise and bench with tools for working pipe up to 3". In the instructor’s office are kept for general use in the shop complete sets up to one inch of twist drills and taps and dies, up to two inches of reamers and mandrils; an assortment of files of various sizes and shapes, of calipers, scales, squares, hammers, chisels, and many other tools. The work-benches are on the same plan as those of the wood-room. They are eight feet long and two and a half feet wide, and have a four and a half inch swivel jaw machinists’ vise on each end; in the centre of rear edge are four cases of tools (two for each vise) and below are four closets. Each tool-case contains the following: One ball-pin hammer, two cold chisels, two cape chisels, one prick punch, six assorted tiles, one scraper, one 4" scale, one 3" machinists’ square, one centre gauge, one scriber, one pair of 6" outside calipers, one pair of 5" inside calipers, one pair 3" outside spring calipers, one pair 5" spring-dividers, one 10" monkey-wrench, one screw-driver, one set of eight lathe cutting tools, one oil-stone, one oil-can, one file card, one pair of copper jaws for vise, and one dust-brush. Each bench will accommodate four students (two on alternate days), each student having a set of tools and a closet to himself. Each machine has a box under it, in which its attachments are kept, and a stool near it for the reception of tools when in use.

The Supply-Room is 14x22 feet, and is fitted up with shelves, racks, cases, etc., for the storage of supplies. A dry-kiln for drying lumber is situated over the boiler-room and heated by steam.

The boiler and coal house is a brick building 22x45 feet detached from the other buildings. Steam is generated by a battery of two sixty-horse power horizontal return tubular boilers, fitted with all modern appliances. One supplies sufficient steam for our needs and the other is kept in reserve. The shops throughout are heated by exhaust steam from the engine and lighted by incandescent lights.

Forge and Foundry

The Catalogue of the Virginia Agricultural and Mechanical College , 1892-’93, pp. 52-53, described the forge and foundry that had been constructed behind the Shop Building for instruction in the "Mechanic Arts" as it was called in those days. Later editions of the catalog described how the building was finally outfitted with equipment.

During last summer a very substantial one-story brick building was erected for use as a Foundry and Forge Shop. The body of the building is 110 feet by 30 feet. At one end there is an L 60 feet by 30 feet and at the other an L 25 feet by 30 feet. The forge shop occupies the 60 feet by 30 feet L and is now partially equipped and in operation.

The foundry is not yet equipped, but is expected to be in running order by the opening of next session. The boiler and coal house is a brick building 22x45 feet detached from the other buildings.

(From the 1908 Catalogue.)

Equipment. -- The Forge Shop is a room 30 x 60 feet, and now contains twenty improved Buffalo forges, with water and coal boxes and down draft attachments; twenty 180-pound Peter Wright anvils; twenty new tool cases, each containing a complete set of forge tools, consisting of four pairs of assorted tongs, one sledge-hammer, one hand-hammer, one set-hammer, one hardie, two blacksmith’s punches, one hot chisel, one cold chisel, one hand punch, one flatter, one bolt header, two pairs tullers, two pairs swages, one fire poker, one small shovel, one 12-inch square, one pair calipers.

One end of the shop is fittted with two work benches having two vises to a bench, and eighteen locked closets beneath for extra tools and unfinished work. A complete set of tools of assorted sizes and shapes are kept by the instructor for special work, and are given to the student when the case demands. A 35-inch Buffalo blower furnishes blast for the forges.

Equipment. -- The Foundry has a floor space of 235 square yards. The equipment of the foundry consists of one 22-inch cupola, moderrn style, air belted, and supplied with air from a Sturtevant blower; one core-oven; one core-table and core-box case; one 800-pound ladle; one 300-pound ladle; two 150-pound ladels and twenty 35-pound ladles; a stock of patterns ranging from a simple block to plain core work, including exercises in snap-board moulding; twenty-five rammers; thirty hand-riddles; twenty-five hand bellows; twenty-five shovels; twenty-five striking rods; twenty-five vent-wires; a full set of flasks for general moulding and twenty-five tool-boxes containing a complete set of moulding tools, one trowel, one lifter, one bench lifter, one yankee slick, one spoon tool, one rubber mallet, one draw spike one gate-cutter, one soft finishing brush, one box of facing, one box of parting sand.

The Brass Foundry occupies a room 50 x 30 feet in connection with the iron foundry. lt is used partly for a supply room for the forge and foundry, and also as a brass foundry. It has one brass furnace with a set of crucibles, lifting tongs and crucible shanks. Regular brass sand is used and flasks suitable for this work.

In one end of this room as office is cut off for the instructor, and a supply of extra tools is kept for the use of forge, foundry and brass foundry.

Addition

The second large addition to the Machine Shops was also completed in September [1904]. The original building was the Preston and Olin Institute, and after the founding of the V. A. M. C, was used as a dormitory until 1888. The two additions to the original building have been placed in such a way as to form a quadrangle, with a small court in the center. This building contains the Wood Working Department, which occupies a room 40 by 110 feet, with a wing 38 by 70 feet, and the Machine Shop Department, which occupies a space 130 by 40 feet, with an "L" 70 by 38 feet. (Alumni Register, 1905, p. 28)

Fire!

In the early morning hours of Saturday morning, June 14, 1913, the V. P. I. shop building was burned to the ground, and one of the most important departments of the college was soon a mass of ruins. But as each alumnus, student, and friend of the college has been notified by President Eggleston, these shops will be at once rebuilt on a bigger and better scale, equipped with the very best and most modern machinery -- this to be done with all the speed compatible with proper construction.

From the Bulletin of the Virginia Polytechnic Institute, Volume VI, No. 3, July, 1913, p. 41.

The following is from the Bulletin of the Virginia Polytechnic Institute, Volume VI, No. 4, October, 1913, pp. 54-55.

Note: Professor Conner was William G. Conner, M.E., associate professor of mechanic arts, and Professor Rasche was William H. Rasche, associate professor of graphics. The "Old Gym" was the Pavilion located on the other side of the Forge and Foundry building. The "Old Laundry" was in between the Pavilion and the Foundry, and was originally built as a machine shop before being converted to a laundry in 1893. The laundry was then moved to a new building in 1903. The reference to "Carneal & Johnson" is in error, the firm was actually "Carneal & Johnston" and it went on to design the McBryde Building of Mechanic Arts, which opened in 1917.

Items Of Interest

The main building of the shops of the Institute, together with its contents, was totally destroyed by fire on the night of June 13, 1913. The forge and foundry buildings and adjacent residences were saved only by the full use of the available fire-fighting facilities. During the summer the wreck was cleaned up and new machinery was purchased. Before the machinery was bought, however, Professors Conner and Rasche visited the leading instructional and commercial shops in the North and Middle West. Most of this machinery has been received and installed and is now in operation. Temporary quarters have been provided in several different buildings. The wood shop is housed in the "Old Gym." Benches for wood working have been provided for forty-four students, and wood-working machinery has been erected in such a manner as to meet temporary needs. As all of the wood-working machinery is individual-motor-driven. it is possible to space it closely. The iron-working machinery is housed in the "Old Laundry" and in that part of the foundry building known as the brass foundry and store-room. The second floor of the first-named building has been fitted up for bench work in iron. The machinery is of the latest type, and it is believed that the equipment will be as complete as that of any instructional shop in the country. The following is a list of the machinery which is now in operation:

Wood Shops Equipment

30 Manual Training lathes each with 1/2 H. P. Motor.

1 6′ Pattern-maker’s lathe with 1/2 H. P. Motor.

1 large 12" lathe with 2 H. P. Motor and full equipment.

1 34" planer with 15 H. P. Motor.

1 10" extra heavy H. P. Smith moulder and matcher with 20 H. P. Motor.

1 band scroll saw with 3 H. P. Motor.

1 heavy band resaw with 10 H. P. Motor.

1 hollow chisel mortiser with 3 H. P. Motor.

1 Falls glue jointer with 5 H. P. Motor.

1 cutoff saw with 5 H. P. Motor.

1 variety saw with 5 H. P. Motor.

1 rip saw with 7-1/2 H. P. Motor.

1 double spindle ball bearing shaper with 3 H. P. Motor.

1 single spindle friezer with dovetailing attachment with 3 H. P. Motor.

1 tenoner with 5 H. P. Motor.

1 combination belt sander with 6 H. P. Motor.

1 disc sander and grinder with 3 H. P. Motor.

1 saw filer.

1 30" grindstone with 1 H. P. Motor.

1 electric grinder with 2 H. P. Motor.

1 6" hand jointer with 6 H. P. Motor.

1 16" hand jointer with 3 H. P. Motor.

Iron-Working Machinery

17 engine lathes of the most modem type.

2 large lathes with all geared heads, motor driven.

1 Pratt and Whitney special tool-maker’s lathe with all attachments.

2 speed lathes.

1 14" shaper, back geared.

1 18" shaper, triple back geared, designed for high speed and heavy duty.

1 small sensitive drill.

1 30" drill.

1 2-1/2 ft. radial drill, motor driven, for heavy work.

3 milling machines of the latest design, all motor driven.

1 30" x 30" x 10 ft. Gray planer, motor driven.

1 8" x 8" air compressor with full equipment of pneumatic tools.

1 small tool cutter and grinder.

1 Brown and Sharp Universal Grinder No. 13.

1 high speed hacksaw machine.

2 tool grinders, belted.

1 tool grinder, motor driven.

1 375 lb. steam hammer.

Carneal & Johnson, the Institute architects, after visiting a number of the shops buildings of the leading institutions of the country, have prepared plans for a new shops building, modeled largely after that at West Point.